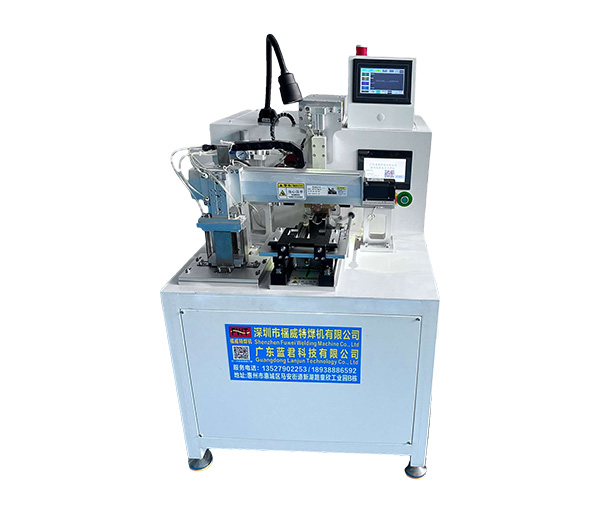

1、 Brief introduction of design scheme

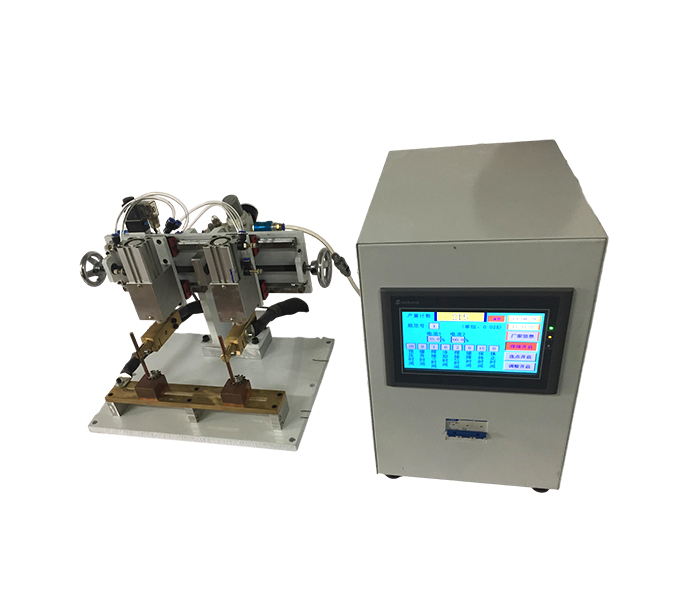

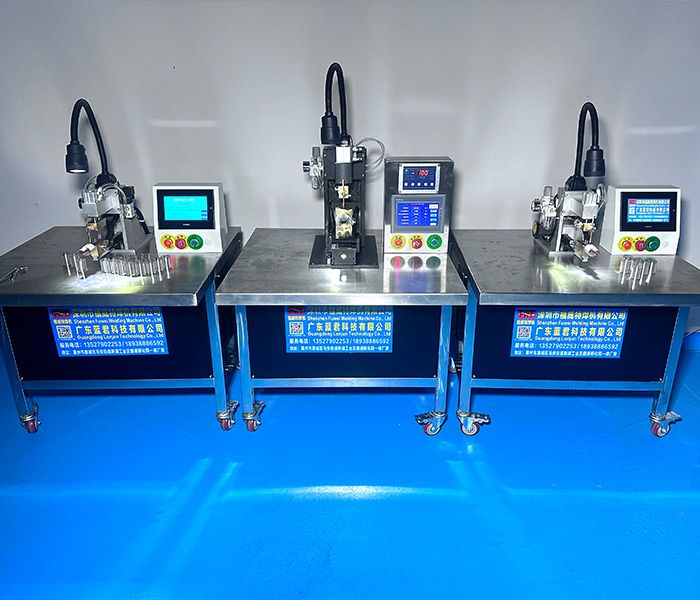

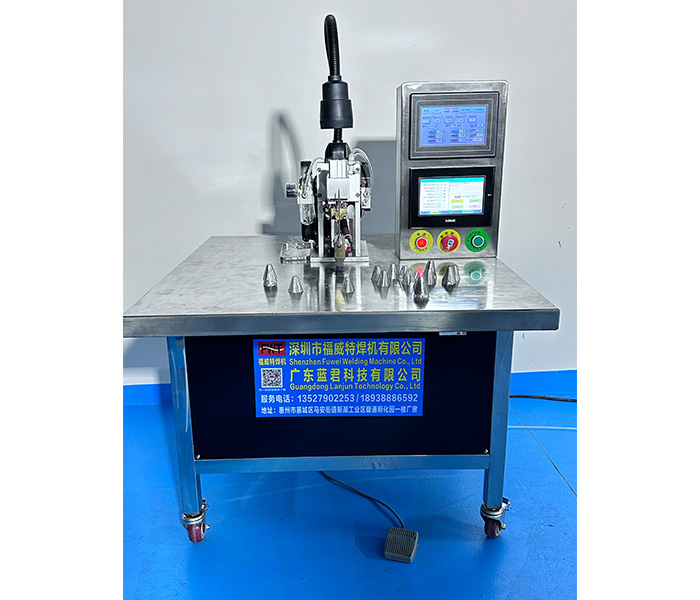

According to the characteristics of your company's products, a high cost performance welding equipment is designed. The TO46 / to56 sealing cap energy storage spot welding machine designed in this scheme has good sealing performance. The welding power supply part of the machine adopts capacitor energy storage discharge welding, which is mainly suitable for packaging and welding of high-power devices such as TO46 / to56, transistors, laser diodes, etc. The transmission part adopts pneumatic pressure, which can ensure enough welding pressure. The flatness of the upper and lower electrodes is ensured by the precise guidance of the four column ball mold. Welding operation is easy and reliable.

1、 Brief introduction of design scheme

According to the characteristics of your company's products, a high cost performance welding equipment is designed. The TO46 / to56 sealing cap energy storage spot welding machine designed in this scheme has good sealing performance. The welding power supply part of the machine adopts capacitor energy storage discharge welding, which is mainly suitable for packaging and welding of high-power devices such as TO46 / to56, transistors, laser diodes, etc. The transmission part adopts pneumatic pressure, which can ensure enough welding pressure. The flatness of the upper and lower electrodes is ensured by the precise guidance of the four column ball mold. Welding operation is easy and reliable. It is widely used in electronic components industry. The capping machine has the functions of adjusting energy storage voltage, charging and discharging, pneumatic pressurization and pneumatic unloading. The machine adopts imported controllable silicon as charge and discharge control, stable and reliable action, perfect protection function, convenient adjustment of process parameters, safe and reliable operation, matching with vacuum gloves and nitrogen filling protection. It is widely used in sealing stone crystal resonator, monolithic crystal filter, clock controlled oscillator, laser diode and temperature compensation crystal oscillator, transistor photoelectric element and small-sized Thermal protector is the first equipment to improve the process of transistor manufacturing enterprises.

Workflow:

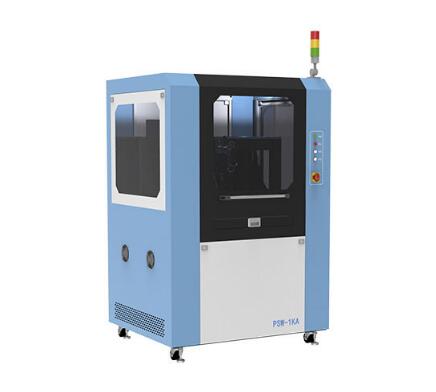

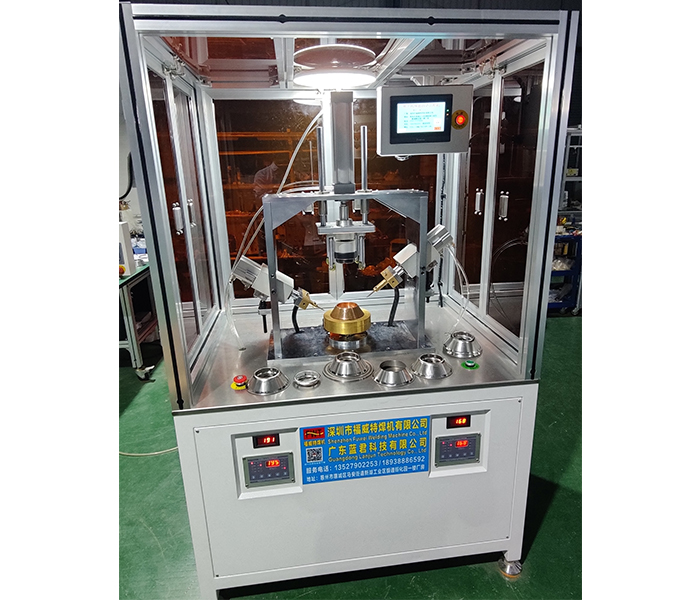

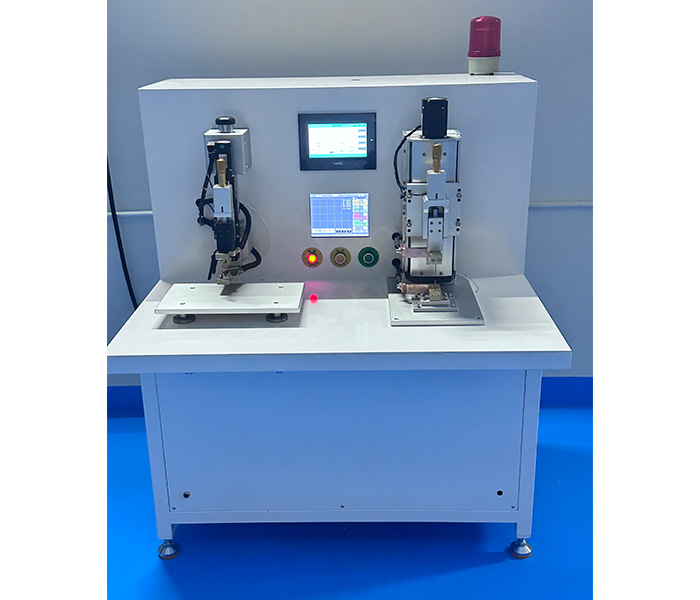

Manually place the workpiece in the left transfer box, then close the left chamber door, and then start the vacuum pump valve for vacuum evacuation; then open the left inner chamber door of the left box from the nitrogen box in the middle main box, put the workpiece into the main box, and weld and seal the cap under the protection of nitrogen; After all welding is completed, open the right chamber door in the main body box, put the welding sealed TO46 into the rightmost heating box for heating, and finally take out the finished product from the right heating box.

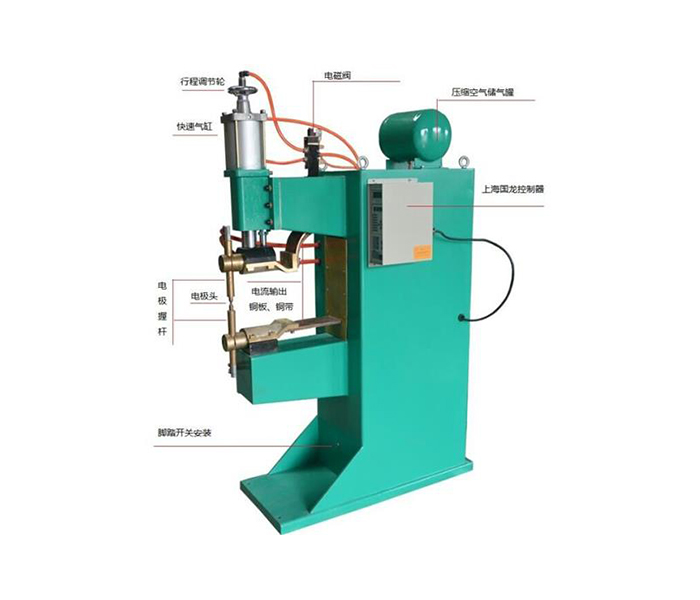

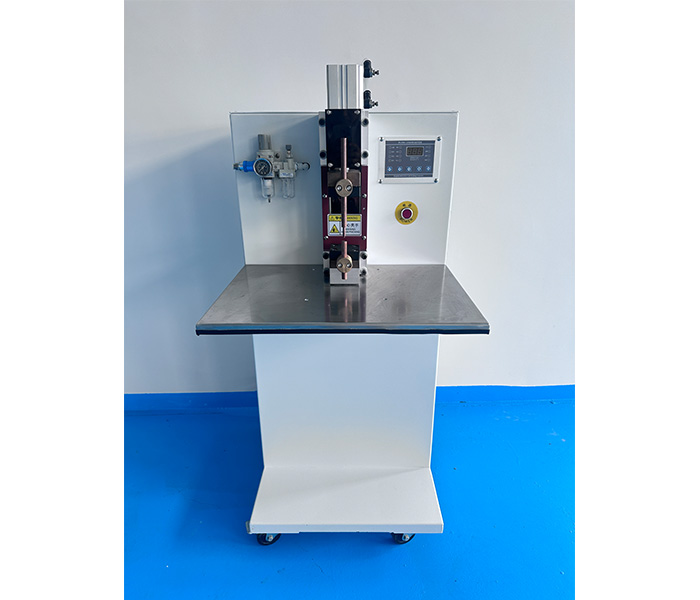

1. Fuselage: the bottom support structure is made of industrial sheet metal, and the surface is oxidized, sprayed and painted, which has a very beautiful appearance and is resistant to dirt; the box on the table is made of 304 stainless steel welding, which has the advantages of long service life, stable structure and strength; it provides enough stress support points and working platform for other action mechanisms.

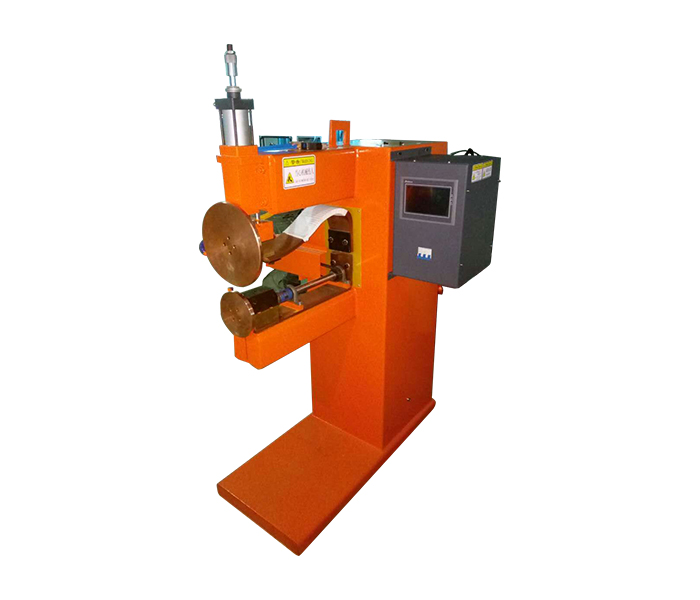

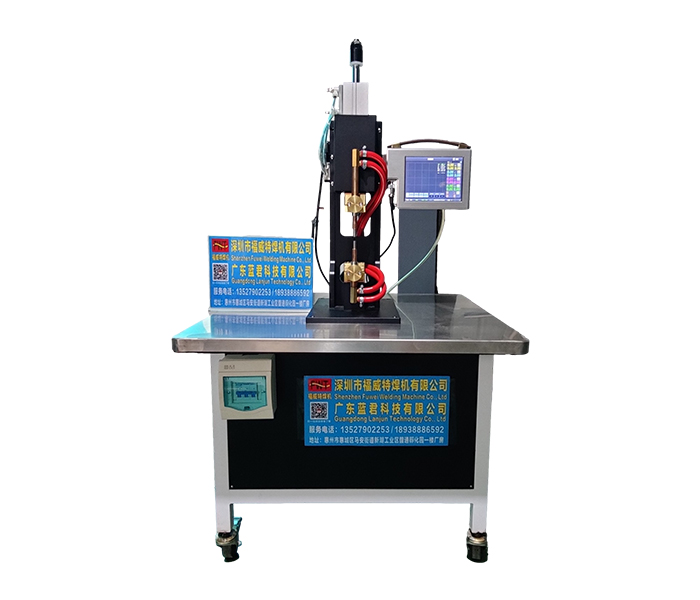

2. Pressurization mechanism: the cylinder is used as the pressure source and controlled by high-quality imported solenoid valve.

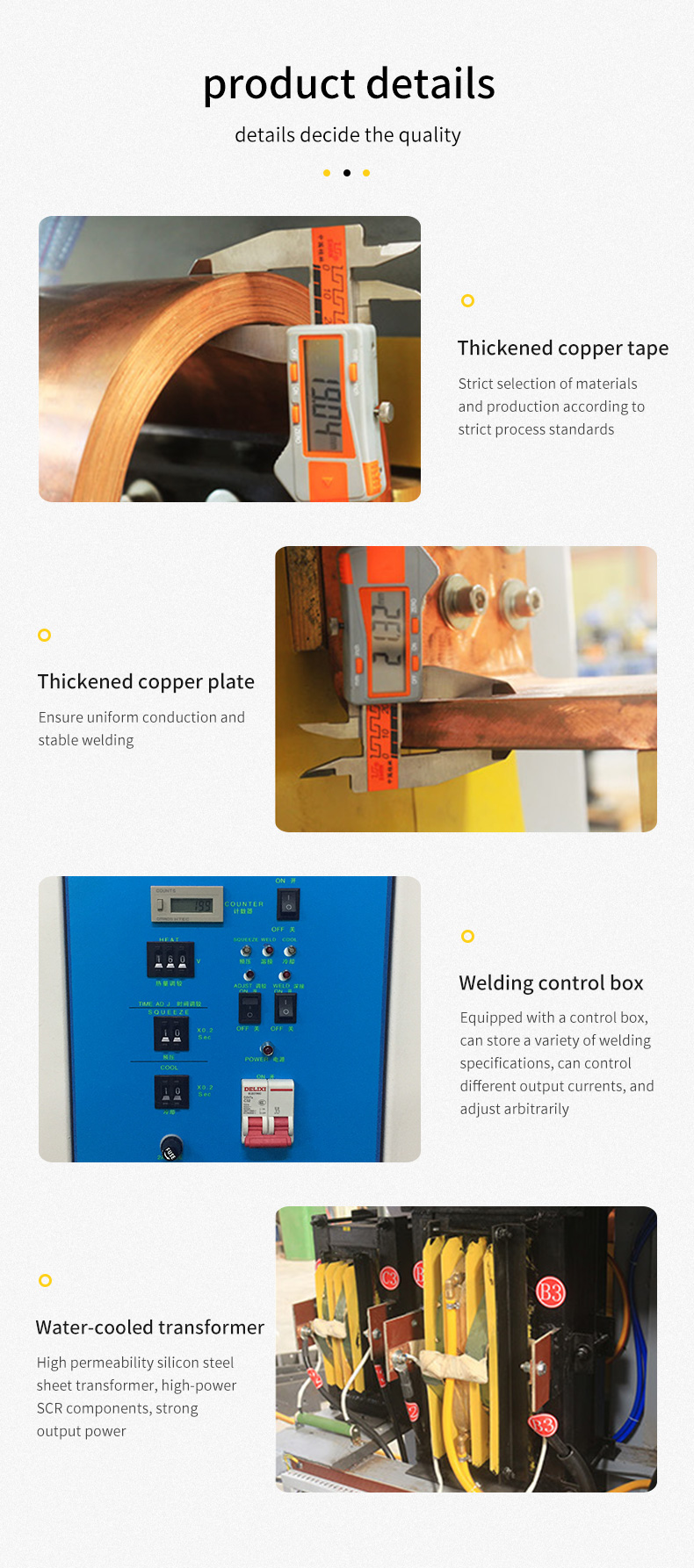

3. Welding power supply: according to the product welding requirements, the capacitor energy storage spot welding machine is selected as the power supply to ensure the stable and strong welding current output of the whole machine and the reliability of the product welding.

4. Operation control system: PLC control circuit, 7 inch LCD touch screen, simple and intuitive operation.

5. Feeding mechanism The design adopts three sealing boxes connected together. The small box on the left side is the transfer door box (welding work pieces are put into the transfer door box first, and then the vacuum pump valve will be opened to drain the air inside). In the middle is a relatively large welding sealing box, which is filled with nitrogen, and the workpiece is welded under the protection of nitrogen (the workpiece in the welding chamber is transferred by the transfer bin) After welding, all the workpieces are transferred to the box of the heating chamber on the right side for heating, and finally the welded workpiece is taken out.

6. Operation system: PLC processor transmits various values, which is easy to operate and adjust welding position and speed.

7. Main features:

(1) Four axis guide pillar guide sleeve head, high precision;

(2) The lower electrode platform X-Y is adjustable;

(3) With dew point meter, with voltage detection;

(4) With heating and vacuumizing;

(5) All 304 stainless steel sealing chamber

二、設(shè)備參數(shù):

| Serial number | project | parameter |

| 1 | Welding power supply | 3KVA |

| 2 | input voltage | 220V |

| 3 | Rated power | 3KVA |

| 4 | Capacitance capacity | 15000UF |

| 5 | Maximum heat output | 1500 J |

| 6 | Welding capacity | Brass 1 + 1, transistor cap diameter: 6mm (0.8-1mm kovar alloy) |

| 7 | Maximum production efficiency | 240 ~ 600 pieces / h |

| 8 | display | 7 inches |

| 9 | Welding head | Four column guiding machine |

| 10 | Adjustable voltage | 1-400V |

| 11 | Maximum electrode pressure | 3000N |

| 12 | Welding cylinder | ?63×50 |

| 13 | Control system | PLC control |

| 14 | Welding method | Manual loading and unloading welding |

| 15 | Total weight | 400KG |

| 16 | Rated air supply pressure | 0.6MPa |

| 17 | Vacuum degree of vacuum chamber | -0.08 MPA |

| 18 | Pressure value of main chamber | -0.01~-0.1MPA |

| 19 | Sealed box cavity | 304 stainless steel material |

| 20 | Welding transformer | GB T2 pure copper |

3、 Equipment materials:

| Serial number | project | brand | Place of Origin |

| 1 | Thyristor | semikron | Germany |

| 2 | touch screen | Display and control | China |

| 3 | Cylinder | AIRTAC | Taiwan, China |

| 4 | Solenoid valve | AIRTAC | Taiwan, China |

| 5 | throttle valve | AIRTAC | Taiwan, China |

| 6 | a sensor | OMRON | Japan |

4、 Equipment manufacturing standards

1. The structure design of the equipment is reasonable, the force is balanced, the surface has no sharp edges and sharp corners, the rotating parts are equipped with protective cover, and the paint is resistant to paint, and the color is in accordance with the company's standard (the color can be customized according to the requirements).

2. The equipment has the function of anti electric shock protection, the wires are not exposed, all wiring harness and gas pipes are arranged in order and beautiful, and the performance standard meets the standard, with strong universality, high precision and reliable performance.

3. The positioning fixture is easy to disassemble, firm and reliable.

4. Make sure to work continuously for 20 hours every day.

5. Mechanism control system, electrical control system, sensitive action, stable performance, simple and safe operation, emergency stop and anti misoperation function.

6. The equipment parameters are set with safety lock to prevent personnel from modifying at will.

7. Device name, label and identification of each switch action.

8. Rating and operating conditions of resistance welding equipment (GB / t8366-2008).

9. Safety requirements for resistance welding machines (GB / 15578-2008).

10. General specification for controller of resistance welding machine (JB / t10110-2008).

11. Fixed spot and projection welding machine (JB / t10101-2000).

12. General specification for resistance welding transformer (JB / t9529-2008).

5、 Preparation of installation site and commissioning by the buyer

1. Distribution board and power line.

2. Equipment connection, ground wire setting (water, electricity, gas to the workstation installation position), primary power supply to the equipment installation site, power supply of 220 v.

3. Auxiliary hoisting equipment required for loading and unloading equipment.

4. The Demander shall provide test pieces for welding test (the specific quantity shall be discussed separately).

5. During the installation and commissioning, the manufacturer shall provide technical training for the demander's technicians, operators and maintenance personnel in terms of machine operation, maintenance, mechanical and electrical maintenance, precautions for use, safety, etc.

6. Other matters not covered.

6、 Overview of equipment technical agreement

1. If there are any increase or decrease or change items in the process of executing the equipment technical agreement, both parties can determine separately based on the principle of bid winning price.

2. The technical agreement, valid quotation and purchase contract constitute the procurement contract documents, which have the same legal effect.

3. There is no cost in the technical agreement.

7、 Requirements and services

1. Execution of technical agreement: Party A and Party B shall manufacture, deliver, commission and accept the equipment in strict accordance with the technical items listed in the technical agreement. In case of any technical bottleneck, either party may propose to the other party a revision of the technical agreement so as to reach a consensus and implement it.

2. The technical agreement is regarded as the index of equipment composition. After the contract is executed, the technical agreement is completed at the same time. As the basis for equipment acceptance, both parties shall conduct acceptance according to the requirements of the technical agreement and the contract as the equipment acceptance standard, and Party A shall sign and receive the acceptance report.

8、 After sales service

Free maintenance for one year, non-human damage, free maintenance, natural disasters, improper operation of damage, depending on the situation, the cost is discussed separately. Lifetime maintenance. When the equipment fails, the repairman will arrive at the site within 48 hours after receiving the repair report.

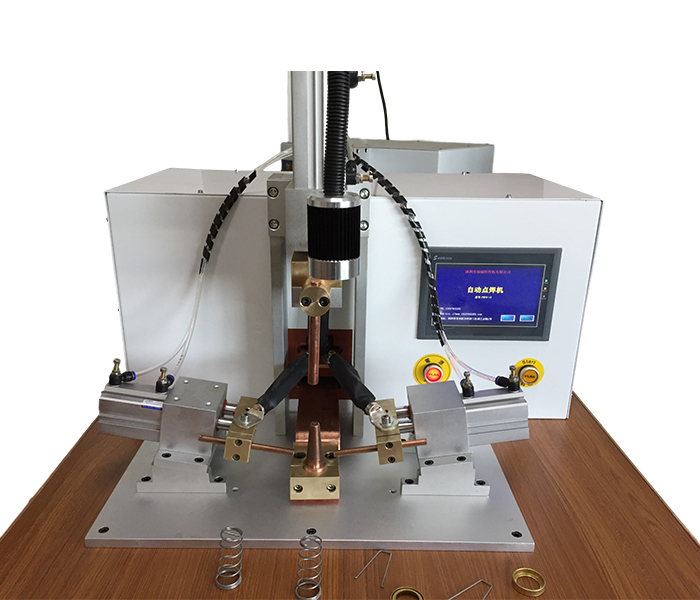

XYZ three axis automatic spot welding machine

Three axis automatic spot welding machine

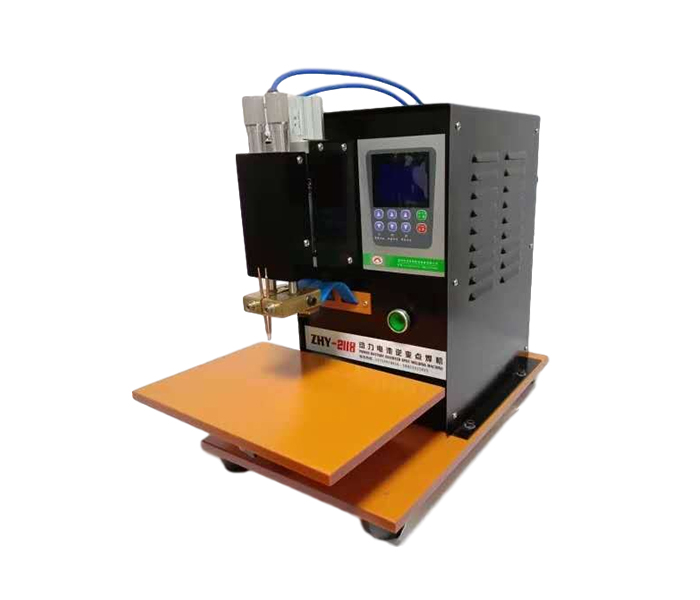

SPW-A50K Electronic pulse spot welding machine

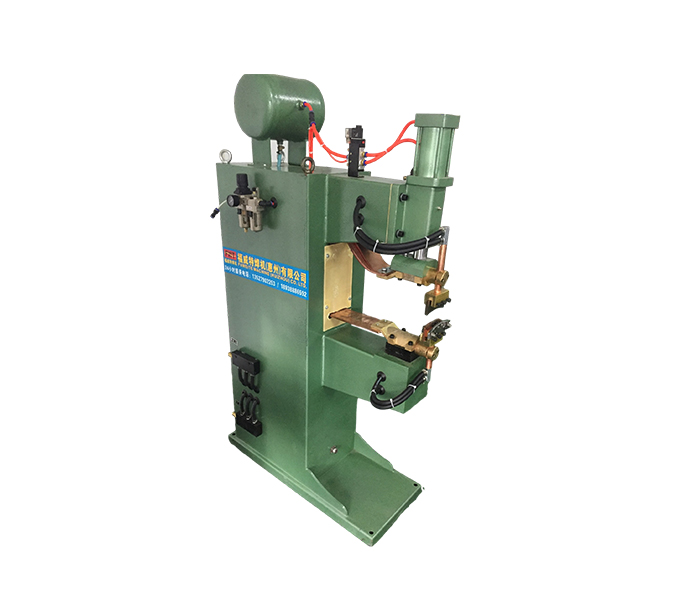

FWT-60 Medium frequency inverter roll welding machine

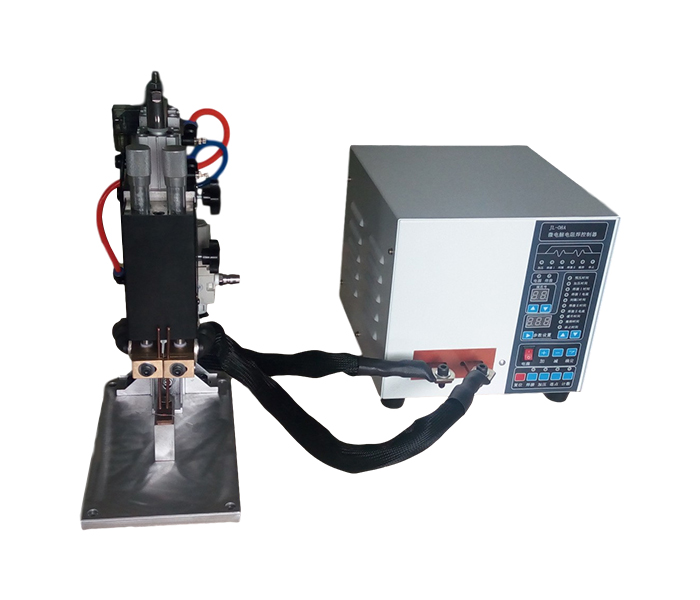

JL-08A Microcomputer resistance welding machine

Power supply of mobile spot welding machine

Linear automatic spot welding machine

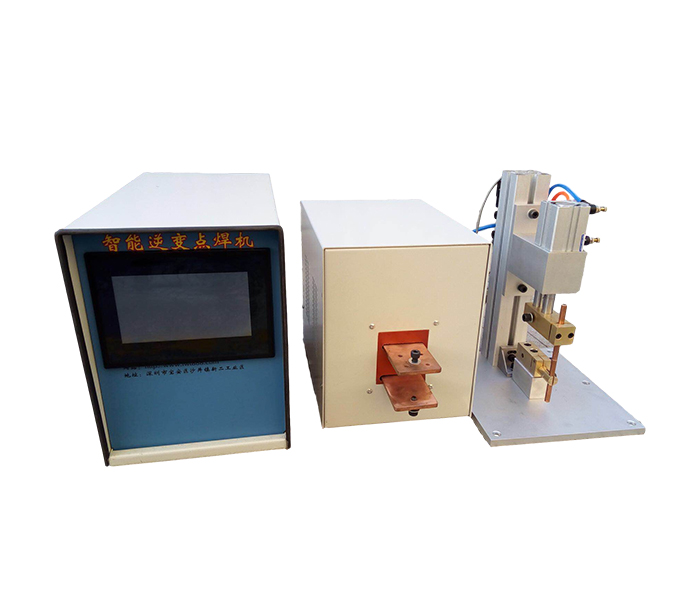

YJD-10AL Inverter DC spot welding machine

Automatic solder spot welder

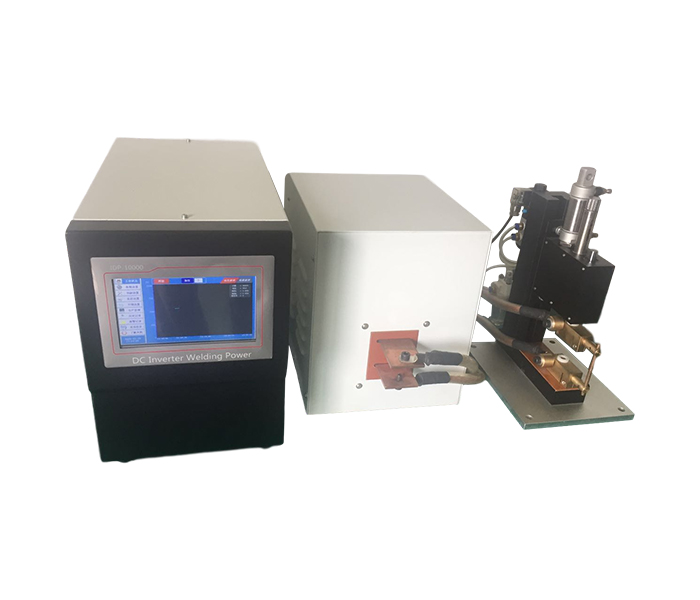

FWT-20000 Medium frequency inverter spot welding machine (air cooled)

FWT-20000 Medium frequency inverter spot welding machine (water cooled)

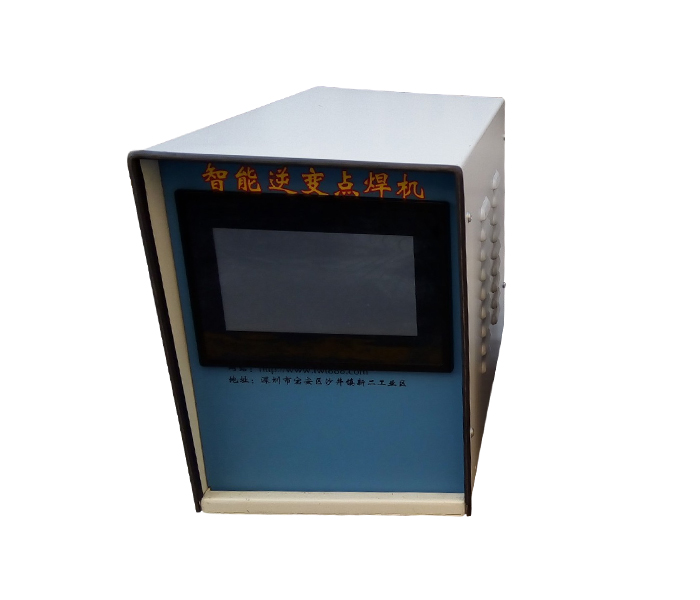

Inverter DC welder power supply

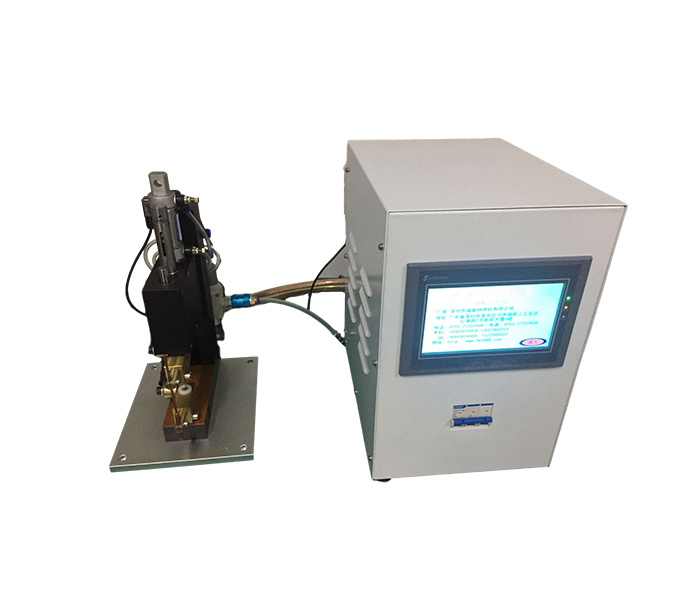

YJD-15AL Intermediate frequency inverter spot welding machine

SAW-DII Capacitor energy storage stud welding machine

CP-101 Capacitive spot welding machine

SCW-3000 capacitive (DC) spot welding machine

TO46 spot welding machine for transistor package

Portable automatic roll welding machine for roof

Convenient spot welding machine yjd-20

Stainless steel filter screen linear spot welding machine

Spring spot welder

Capacitor spot welding machine cp-6ca

點(diǎn)焊機(jī)

Power supply sp-330 for capacitive spot welding machine

Resistance welding machine

Special spot welding machine for stapler and punching machine

High frequency battery spot welding machine

v

Automatic stud welding machine

Hand held spot welding machine

Double head movable chest button spot welding machine

Table type precision spot welding machine

Microcomputer precision resistance welding machine

Linear resistance welding machine

Intermediate frequency butt welder

Intermediate frequency inverter spot welder fwt-40ka

Medium and high frequency inverter DC bump welding machine

Medium frequency inverter welding machine

Filter screen automatic spot welding machine

Automatic spot welding machine for filter screen

Filter linear spot welding machine

Automatic spot welding machine for filter bottom cover

Fully automatic spot welding machine for filter screen

Mid frequency inverter spot welding machine

Precision resistance welding machine

Precision resistance welding machine

Capacitive energy storage spot welding machine

Filter linear spot welding machine

Filter linear DC spot welding machine

Dual position servo spot welding machine

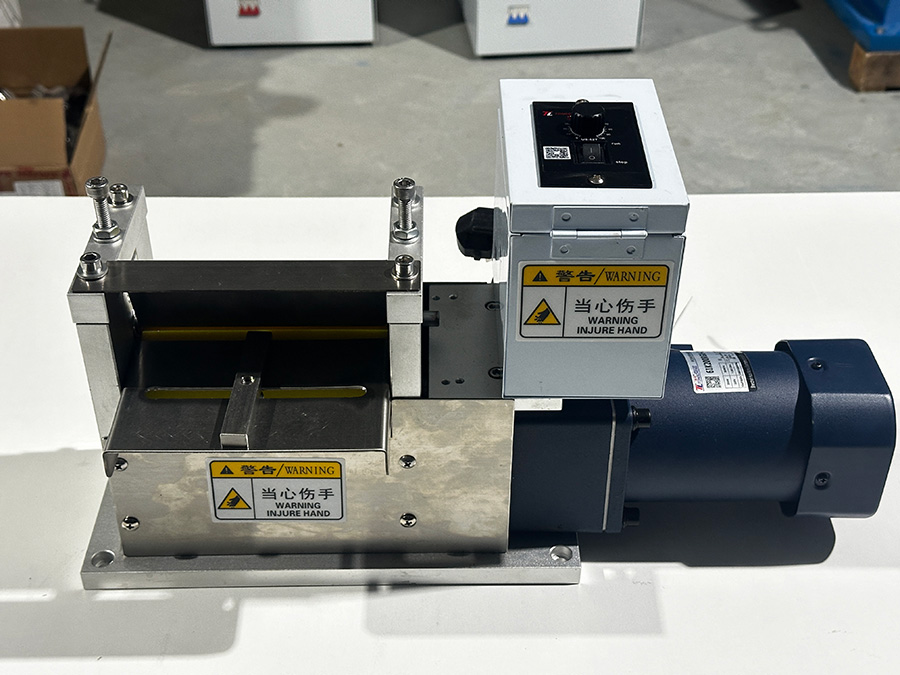

Small coiling machine

Filter forming automatic spot welding machine